Kendo Bogu - Quality vs Price at its best. Starting from $395.

Our Flagship Bogu: The Haechi

This premium 6mm set is our flagship bogu favored by high-rank senseis as well as beginners. Starting from $675, this set is highly recommended.

First time buying a Kendo bogu?

FREE CONSULTATION BEFORE YOU BUY.

For many reasons, we ask you to schedule a free consultation session, so we can listen to your needs, and give you a guided consultation, to find you a bogu set within your budget.

Fill out our free consultation questionnaire, and we will reach out to you to schedule a Zoom call to help you decide. We don’t expect you to just pick a bogu from our online shop and purchase something solely based on a few fancy photos. We are here to help you make the correct decision.

Before you drop a couple of hundred dollars on a bogu set, make sure you understand what you are purchasing because you will be using this for a long time.

Understand the difference between machine-stitched vs hand-stitched bogu, the different stitch widths, the stitch patterns, what materials are used, and for what level of Kendo you will all round up to get you that perfect bogu for your Kendo experience and journey.

Kendo bogu, comes in two big categories. Machine-stitched vs Hand-stitched (tezashi). The majority of bogu out in the market are machine-stitched, and with technology advancements, the machine-stiched bogu are great in quality.

If you have done your research before reading this, you probably saw 2mm, 3mm, 4mm, 5mm, and other measurements. These indicate the distance between the stitch lines, and the small width, the padding material (futon) and fabric will be more dense, and allow for increased durability and improved ability to keep its shape. However, the increased stitching makes the padding more compact and sacrifices the ability to absorb impact. Wider stitches such as 6mm or more will improve impact absorption, and be more “cushiony” to feel more comfortable, however, the bogu will likely be heavier, and less willing to hold shape, and decrease durability due to less stitching.

Moving away from the stitch width, you have options for cross-stitch patterns to stiffen the futon for increased durability and resilience. There is an option for naname-zashi, which means the stitch pattern which is at a diagonal angle, and is usually implemented on the men-dare (shoulder protecting wings on the men), and is mainly for design purposes. No significant functional value is added.

The futon, the indigo blue material, is the main material used throughout the bogu construct and is made of layers of cotton, and felt padding. The paddings are layered and stitched together, thus the wider the stitch, otherwise, less stitching, causes less compacting, allowing for more impact absorption, and narrow stitch width, or increased stitch numbers increases the compression for decreased impact absorption.

Tezashi bogu, or hand-stitched bogu, comes with a higher price tag and is usually related to a customized set for a perfect fit. The measurements are referred to bu, instead of mm, and 1 bu is equivalent to 3.03mm. The range is usually 1 bu, 1.2 bu, 1.5 bu, 2 bu, 2.5 bu or 3 bu. The principle of impact absorption vs durability vs shape is same as machine-stitched sets. The square stitch pattern of tezashi sets sometimes has an added stitch in the center of the “block” and this is called gunome-zashi, and this helps in improving the shaping of the bogu.

Moving onto the face guard, the metal grid, or mengane, is another factor. Duralumin, aluminum, and titanium are all options and decided on the durability and weight, and of course price.

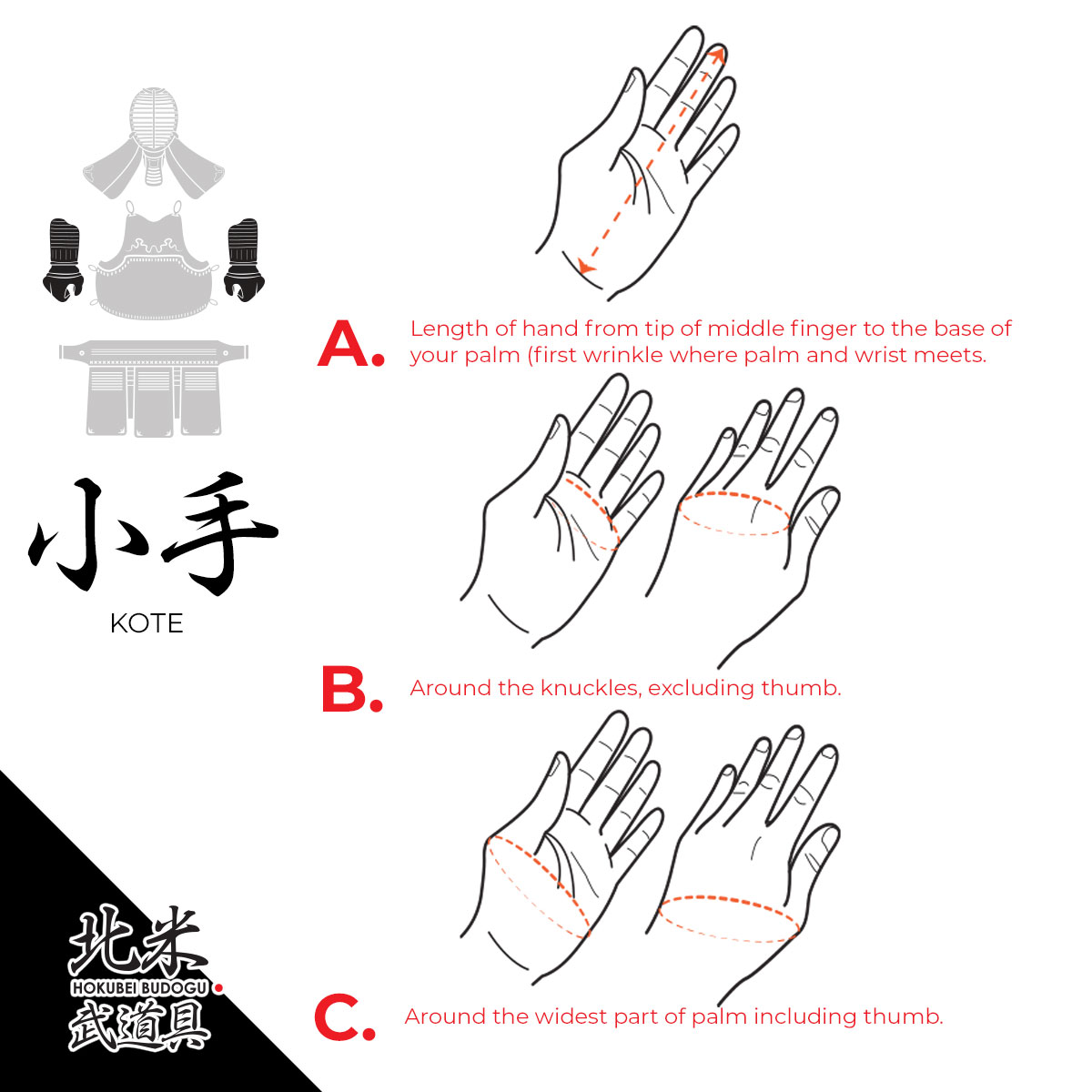

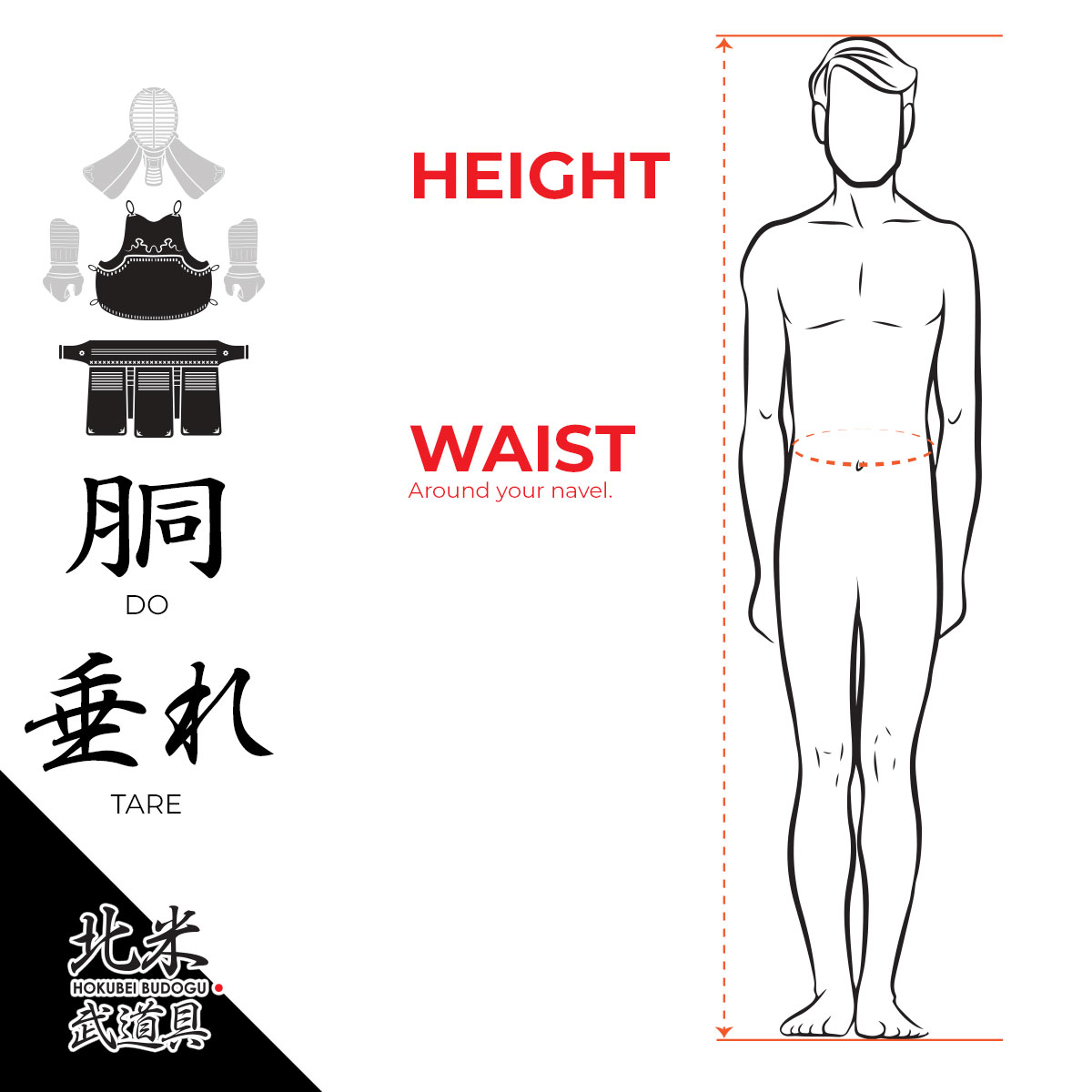

Even this long paragraph only scratches the surface of the amount of details involved in bogu selection. This is a portion of just the helmet or men. We still have to consider the gloves (kote), the torso guard (do), and thigh protectors (tare). This is why we encourage you to contact us to schedule a free consultation to allow us to help you make the correct selection of stitch, style, materials, size, and budget.